Modbus over TCP In the realm of industrial automation and control systems, communication protocols are the unsung heroes that enable seamless interaction between devices. Among these protocols, Modbus over TCP stands out for its simplicity, reliability, and widespread adoption. This guide delves into the intricacies of Modbus over TCP, elucidating its operation, advantages, and implementation strategies. Whether you’re an engineer, technician, or simply a technology enthusiast, mastering Modbus over TCP will enhance your understanding of industrial communications and improve your system’s efficiency.

Understanding Modbus Over TCP

Origins and Evolution

Modbus, developed by Modicon in 1979, was originally designed for serial communication over RS-232 and RS-485 interfaces. It quickly became a de facto standard due to its straightforward and open nature. With the advent of Ethernet technology, Modbus evolved to leverage TCP/IP, giving birth to Modbus over TCP. This adaptation allowed for faster, more reliable communication over longer distances, making it ideal for modern industrial networks.

How Modbus Over TCP Works

At its core, Modbus over TCP follows a client-server architecture. The client, typically a computer or programmable logic controller (PLC), sends requests to the server, which could be a variety of devices such as sensors, actuators, or other PLCs. These requests involve reading from or writing to specific memory locations within the server device, facilitating real-time data exchange and control.

The Protocol Structure

Modbus over TCP encapsulates Modbus protocol data units (PDUs) within TCP/IP packets. The typical Modbus PDU consists of a function code, data, and error-checking information. The TCP layer adds further reliability and ensures data integrity during transmission.

Key Components

- Function Codes: These define the type of action requested by the client, such as reading coils, reading discrete inputs, writing single coils, or writing multiple registers.

- Data Units: These include the specific addresses and values being read or written.

- Transaction Identifier: A unique identifier used to match requests with responses.

Advantages of Modbus Over TCP

Scalability and Flexibility

One of the primary benefits of Modbus over TCP is its scalability. Ethernet networks can support a virtually unlimited number of devices, allowing for expansive and complex systems. This flexibility is crucial for industries that require integration of numerous devices across large facilities.

Enhanced Data Throughput

Modbus over TCP leverages the high-speed capabilities of Ethernet, providing faster data transfer rates compared to traditional serial Modbus. This enhancement is particularly beneficial for applications requiring real-time data processing and control.

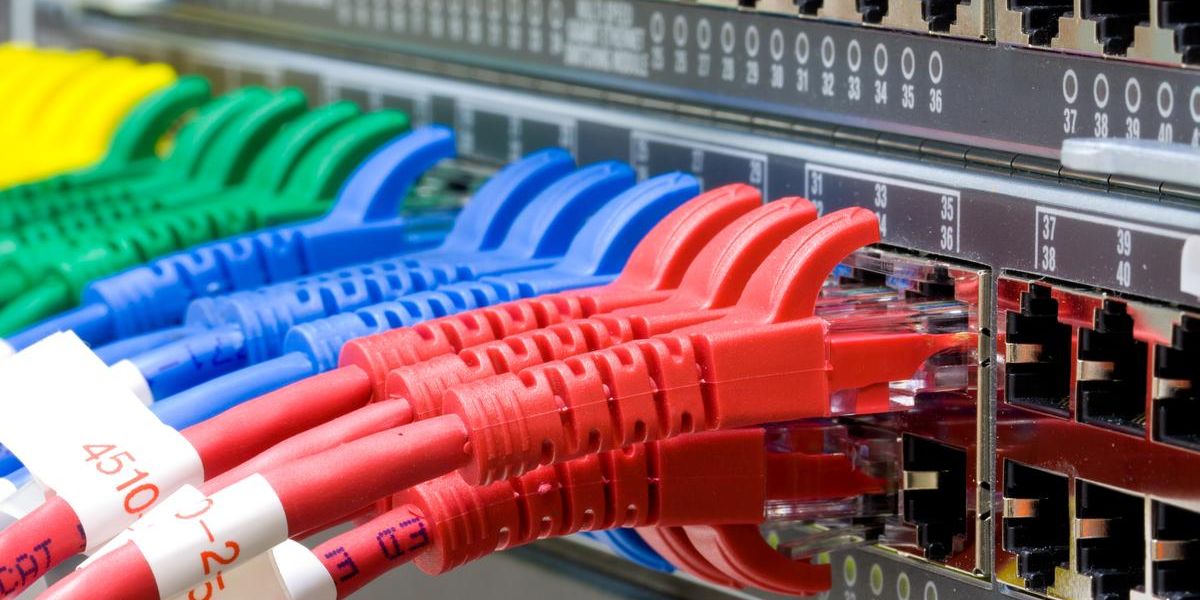

Simplified Wiring and Installation

By utilizing standard Ethernet infrastructure, Modbus over TCP simplifies the wiring and installation process. This reduces the need for specialized cabling and connectors, lowering overall installation and maintenance costs.

Improved Reliability and Error Handling

TCP/IP includes built-in error checking and correction mechanisms, ensuring reliable data transmission even in noisy environments. This robustness is a significant advantage over serial communication, where data integrity can be compromised by interference.

Implementing Modbus Over TCP

Setting Up the Network

Implementing Modbus over TCP begins with setting up a robust and well-planned Ethernet network. Key considerations include network topology, device addressing, and ensuring adequate bandwidth for the intended data traffic.

- Network Topology: Choose a topology that best suits your application. Common topologies include star, ring, and mesh networks.

- IP Addressing: Assign unique IP addresses to each device on the network. Static IP addresses are often preferred for critical devices to avoid address conflicts.

- Switches and Routers: Use industrial-grade switches and routers to ensure reliable and secure communication.

Configuring Devices

Each device participating in Modbus over TCP must be properly configured. This involves setting the correct IP address, subnet mask, and gateway. Additionally, ensure that each device is capable of handling the specific Modbus function codes required for your application.

- Modbus Master (Client): Configure the client device to send requests to the appropriate IP addresses of the server devices.

- Modbus Slave (Server): Configure the server devices to respond to the client’s requests and perform the necessary read/write operations.

Software Implementation

Several software solutions are available for implementing Modbus over TCP. These range from dedicated Modbus libraries for various programming languages to comprehensive industrial automation software suites.

- Libraries: Popular programming languages such as Python, C++, and Java have libraries that simplify Modbus over TCP implementation.

- SCADA Systems: Supervisory Control and Data Acquisition (SCADA) systems often include built-in support for Modbus over TCP, providing a user-friendly interface for configuring and monitoring devices.

Security Considerations

While Modbus over TCP offers numerous advantages, it also introduces potential security risks due to its reliance on Ethernet and IP networks. Implementing robust security measures is crucial to protect your system from unauthorized access and cyber threats.

- Firewalls: Use firewalls to control access to your Modbus network and prevent unauthorized devices from communicating with critical systems.

- VPNs: Virtual Private Networks (VPNs) provide secure, encrypted communication channels for remote access to your Modbus network.

- Authentication and Encryption: Implement authentication mechanisms to ensure that only authorized users can access the network. Consider using encryption to protect data during transmission.

Troubleshooting Modbus Over TCP

Common Issues and Solutions

Despite its robustness, Modbus over TCP systems can encounter various issues. Understanding common problems and their solutions can help ensure smooth operation.

- Network Congestion: High network traffic can lead to delays and timeouts. Use Quality of Service (QoS) settings to prioritize Modbus traffic.

- Address Conflicts: IP address conflicts can disrupt communication. Ensure each device has a unique IP address and use static IPs for critical devices.

- Firewall Blocking: Incorrect firewall settings can block Modbus traffic. Configure firewalls to allow Modbus over TCP communication on the designated ports (usually port 502).

Diagnostic Tools

Several diagnostic tools are available to assist in troubleshooting Modbus over TCP systems. These tools can help identify and resolve communication issues, ensuring optimal performance.

- Network Analyzers: Tools like Wireshark allow you to capture and analyze network traffic, helping identify issues at the packet level.

- Modbus Simulators: Simulators enable you to test and debug Modbus communication without the need for actual hardware devices.

- Ping and Traceroute: Basic network utilities like ping and traceroute can help identify connectivity issues and pinpoint network bottlenecks.

Future Trends in Modbus Over TCP

Integration with IoT and Industry 4.0

As the Internet of Things (IoT) and Industry 4.0 continue to advance, Modbus over TCP is poised to play a critical role in the integration of industrial devices and systems. The ability to connect and communicate with a wide range of devices over Ethernet makes Modbus over TCP an ideal protocol for IoT applications.

Enhanced Security Protocols

Given the increasing importance of cybersecurity, future developments in Modbus over TCP are likely to focus on enhanced security protocols. This includes more robust authentication methods, encryption standards, and anomaly detection mechanisms to protect against evolving cyber threats.

Advanced Diagnostic and Monitoring Tools

Advancements in diagnostic and monitoring tools will continue to improve the ability to troubleshoot and optimize Modbus over TCP systems. AI-driven analytics and predictive maintenance tools will provide deeper insights into network performance and potential issues.

Interoperability with Other Protocols

As industrial communication networks become more complex, interoperability between different protocols will become increasingly important. Future developments may focus on seamless integration between Modbus over TCP and other industrial protocols such as OPC UA, MQTT, and BACnet.

Modbus over TCP

Mastering Modbus over TCP is essential for anyone involved in industrial automation and control systems. Its simplicity, reliability, and scalability make it a powerful tool for modern industrial networks. By understanding its operation, advantages, and implementation strategies, you can leverage Modbus TCP to enhance your system’s efficiency and performance.

From setting up the network and configuring devices to implementing robust security measures and troubleshooting common issues, this guide has provided a comprehensive overview of Modbus over . As technology continues to evolve, staying informed about the latest trends and advancements will ensure that you remain at the forefront of industrial communication and automation.

More Stories

Unlock Secrets of Behrouz Forouzan’s Data Communication Mastery

Discover Topology in Data Communication for Better Networks

Master Modbus Over TCP IP for Seamless Connectivity